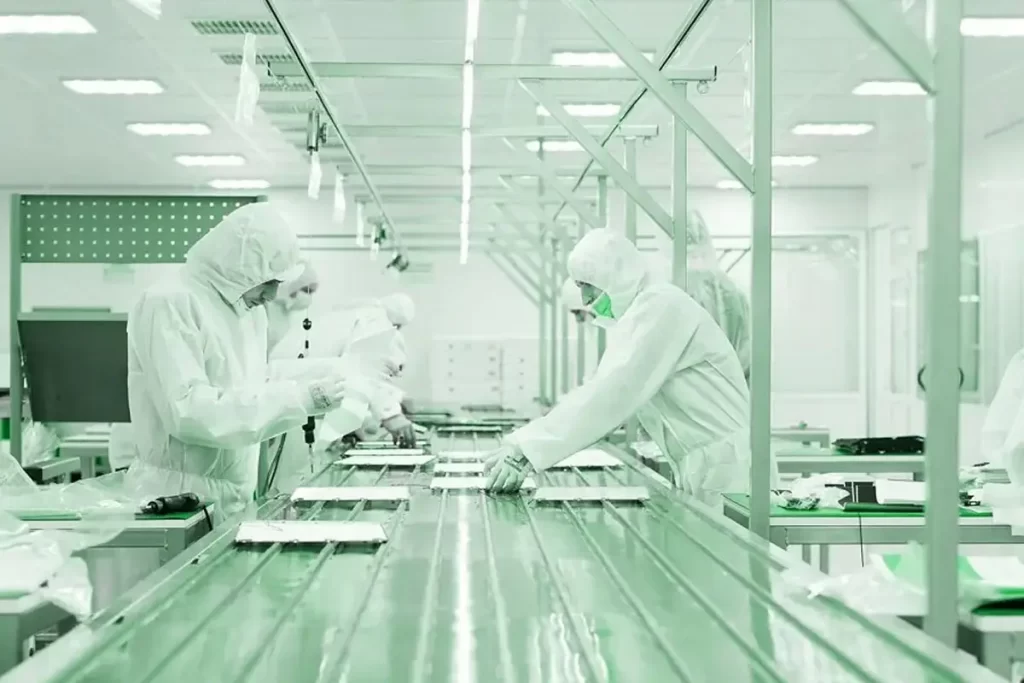

A cleanroom is a controlled environment used for the production of sensitive products and components. In a cleanroom, suspended particles and contaminants are minimized to prevent the degradation of product quality and components. Cleanrooms are used in a variety of industries, including:

Pharmaceutical Industry

Cleanrooms in the pharmaceutical industry are used to produce drugs, vaccines, and other pharmaceutical products. These products must be free of any contamination to ensure their safety and efficacy.

Applications of cleanrooms in the pharmaceutical industry:

- Production of injectable drugs: Injectable drugs must be free of any contamination to prevent infection in the patient. Cleanrooms are used to produce injectable drugs to prevent contamination from entering the drug.

- Production of vaccines: Vaccines contain biological materials that are easily contaminated. Cleanrooms are used to produce vaccines to prevent contamination from entering the vaccine.

- Production of sensitive pharmaceutical products: Some pharmaceutical products are sensitive to contamination. Cleanrooms are used to produce these products to prevent contamination from entering the product.

read more| Package unit

Cleanroom Equipment in the Pharmaceutical Industry

Cleanrooms in the pharmaceutical industry must have certain equipment to prevent contamination from entering the room. Some of the equipment used in cleanrooms in the pharmaceutical industry include:

- HVAC system: The cleanroom HVAC system should be designed to control temperature, humidity, and air quality.

- Air filtration system: The air filtration system should be designed to remove particulates from the air.

- Access control system: The access control system should be designed to restrict access to people in the cleanroom.

- Laundry system: The laundry system should be designed to wash the clothes of cleanroom workers.

Benefits of using cleanrooms in the pharmaceutical industry

Using cleanrooms in the pharmaceutical industry has many advantages, including:

- Improved safety of pharmaceutical products: Cleanrooms help to produce safer pharmaceutical products.

- Increased effectiveness of pharmaceutical products: Cleanrooms help to increase the effectiveness of pharmaceutical products.

- Reduced cost of drug production: Cleanrooms help to reduce the cost of drug production.

Cleanrooms play an important role in the production of safe and effective pharmaceutical products. Cleanrooms prevent contamination from entering pharmaceutical products by controlling the number of particulates in the air.

read more | Cleanroom Design

Application of cleanrooms in the semiconductor industry

Cleanrooms are used in the semiconductor industry to produce sensitive electronic components and circuits. A cleanroom is a controlled environment in which the level of particulates and contaminants is severely limited. This is essential for the production of sensitive electronic components and circuits that are sensitive to contamination.

The applications of cleanrooms in the semiconductor industry include:

- Production of semiconductor chips: Semiconductor chips are made from sensitive materials that are sensitive to contamination. A cleanroom is essential for the production of semiconductor chips to prevent their contamination.

- Production of integrated circuits: Integrated circuits are made from semiconductor chips. A cleanroom is essential for the production of integrated circuits to prevent contamination of semiconductor chips.

- Production of sensitive electronic components: Sensitive electronic components such as sensors and transistors are sensitive to contamination. A cleanroom is essential for the production of sensitive electronic components to prevent their contamination.

The degree of cleanliness of a cleanroom in the semiconductor industry depends on the type of product being produced. For the production of high-tech semiconductor chips, a cleanroom with a very high degree of cleanliness is required.

read more | Cleanroom Validation

Types of Cleanrooms in Semiconductor Industries

Cleanrooms in the semiconductor industry are divided into two types: laminar flow and non-laminar flow.

Laminar flow cleanroom: In a laminar flow cleanroom, the air flows in a layer in one direction. This type of cleanroom is suitable for the production of sensitive electronic components and circuits that are sensitive to contamination.

Non-laminar flow cleanroom: In a non-laminar flow cleanroom, the air flows irregularly in the room. This type of cleanroom is suitable for the production of less sensitive electronic components and circuits.

Cleanroom equipment in semiconductor industries

Cleanrooms in semiconductor industries require a variety of equipment, including:

- Air conditioning system: The air conditioning system is used to control the temperature, humidity, and air pressure in the cleanroom.

- Air filtration system: The air filtration system is used to remove suspended particles and contaminants from the air.

- Control systems: Control systems are used to monitor the environmental conditions of the cleanroom.

- Personal protective equipment: Personal protective equipment such as special clothing and shoes are used to prevent contamination of the cleanroom.

Application of cleanrooms in food and cosmetics industries

Cleanrooms are used in the food and cosmetics industries to produce high-quality and safe products. These rooms create a contamination-free environment through precise filtration systems, controlled humidity and temperature, and controlled airflow.

read more | cleanroom equipment

Application of Cleanrooms in the Food Industry

In the food industry, cleanrooms are used to produce products such as drugs, dietary supplements, and sensitive foods. These products often contain sensitive ingredients such as vitamins, minerals, and antioxidants that can be damaged by exposure to contamination. Cleanrooms prevent damage to these products by creating a contamination-free environment.

Some specific applications of cleanrooms in the food industry include:

- Production of drugs and dietary supplements

- Food packaging

- Production of dairy and meat products

- Production of bakery products

- Production of canned products

Application of Cleanrooms in the Cosmetic and Personal Care Industry

In the cosmetic and personal care industry, cleanrooms are used to produce products such as cosmetics, skincare products, and haircare products. These products often contain sensitive ingredients such as colors, fragrances, and preservatives that can be damaged by exposure to contamination. Cleanrooms prevent damage to these products by creating a contamination-free environment.

Some specific applications of cleanrooms in the cosmetic and personal care industry include:

- Production of cosmetics

- Production of skincare products

- Production of haircare products

- Testing of cosmetic and personal care products

read more | Cleanroom stainless steel equipment

Benefits of Using Cleanrooms in the Food and Cosmetic Industries

The use of cleanrooms in the food and cosmetic industries has many benefits, including:

- Improved product quality: Cleanrooms create a contamination-free environment that prevents damage to products and increases product quality.

- Product safety: Cleanrooms create a contamination-free environment that prevents the transmission of diseases and contamination to products.

- Reduced costs: Cleanrooms can help reduce production costs and product recalls by increasing product quality and safety.

Application of Cleanrooms in the Electronics Industry

A cleanroom is a controlled environment used for the production of sensitive products and components. Cleanrooms have a high degree of cleanliness and prevent contamination from entering the environment.

Cleanrooms have many applications in the electronics industry, including:

- Production of electronic components and circuits: Cleanrooms are used to produce sensitive electronic components and circuits. Contamination can reduce the quality and performance of electronic components and circuits. Cleanrooms help to produce high-quality electronic components and circuits by preventing contamination from entering the environment.

- Assembly of electronic components: Cleanrooms are used to assemble sensitive electronic components. Contamination can cause short circuits and other problems in circuits. Cleanrooms help to assemble high-quality electronic components by preventing contamination from entering the environment.

- Testing of electronic components and circuits: Cleanrooms are used to test sensitive electronic components and circuits. Contamination can cause errors in test results. Cleanrooms help to test electronic components and circuits with high accuracy and precision by preventing contamination from entering the environment.

read more | Cleanroom Garment Box

Cleanroom Cleanliness Class in the Electronics Industry

The cleanliness class of a cleanroom in the electronics industry depends on the type of electronic components and circuits involved. In general, cleanrooms with higher cleanliness classes are used to produce more sensitive electronic components and circuits.

The cleanliness class of a cleanroom in the electronics industry is defined by the ISO 14644-1 standard. This standard is defined based on the number of suspended particles per unit volume of air. The cleanliness class of a cleanroom in the electronics industry typically ranges from ISO 1 to ISO 9.

The Benefits of Cleanrooms in the Electronics Industry

The use of cleanrooms in the electronics industry has many advantages, including:

- Improved quality of electronic components and circuits: Cleanrooms help to improve the quality of electronic components and circuits by preventing contamination.

- Reduced waste and production costs: Cleanrooms help to improve productivity by reducing waste and production costs.

- Increased safety of products and equipment: Cleanrooms help to increase the safety of products and equipment by preventing contamination.

Cleanrooms are an essential tool in the electronics industry. With their many advantages, cleanrooms help to improve quality, safety, and productivity in these industries.

Applications in the Aerospace Industry

A cleanroom is a controlled environment that is used to produce sensitive products and components. Cleanrooms have a high degree of purity and prevent contamination from entering the environment.

Cleanrooms have many applications in the aerospace industry, including:

- Production of aircraft and spacecraft parts and components: Cleanrooms are used to produce sensitive aircraft and spacecraft parts and components. Contamination can reduce the performance and safety of aircraft and spacecraft. Cleanrooms help to produce high-quality aircraft and spacecraft parts and components by preventing contamination.

- Assembly of aircraft and spacecraft: Cleanrooms are used to assemble sensitive aircraft and spacecraft. Contamination can cause assembly errors and reduce the performance of aircraft and spacecraft. Cleanrooms help to assemble high-quality aircraft and spacecraft by preventing contamination.

- Testing of aircraft and spacecraft: Cleanrooms are used to test sensitive aircraft and spacecraft. Contamination can cause errors in test results and reduce the safety of aircraft and spacecraft. Cleanrooms help to test aircraft and spacecraft with high accuracy and precision by preventing contamination.

Cleanroom cleanliness classes in the aerospace industry

The cleanliness class of a cleanroom in the aerospace industry depends on the type of aircraft and spacecraft components in question. In general, cleanrooms with higher cleanliness classes are used to produce more sensitive aircraft and spacecraft components.

The cleanliness class of a cleanroom in the aerospace industry is determined by the ISO 14644-1 standard. This standard is defined based on the number of suspended particles per unit volume of air. The cleanliness class of a cleanroom in the aerospace industry typically ranges from ISO 5 to ISO 9.

read more | Cleanroom Control and Monitoring

Specific applications of cleanrooms in industries

- Production of sensitive materials and components: Cleanrooms are used to produce sensitive materials and components. Contamination can reduce the quality of sensitive materials and components. By controlling suspended particles and contaminants, cleanrooms help to prevent the reduction of quality of sensitive materials and components.

- Weighing and sampling: Cleanrooms are used for weighing and sampling of sensitive materials and products. Contamination can reduce the accuracy and precision of weighing and sampling. By controlling suspended particles and contaminants, cleanrooms help to improve the accuracy and precision of weighing and sampling.

- Scientific experiments: Cleanrooms are used to conduct sensitive scientific experiments. Contamination can reduce the accuracy and precision of scientific experiments. By controlling suspended particles and contaminants, cleanrooms help to improve the accuracy and precision of scientific experiments.

By controlling suspended particles and contaminants, cleanrooms help to prevent the reduction of quality of products and production processes, and improve the safety and health of employees.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: